Project Description

“Piña” fiber is extracted from the leaves of a pineapple plant. Its scientific name is ananas comosus. The fibers are ivory-white in color and naturally glossy. The cloth is translucent, soft and fine with high luster. Piña fiber is often blended with cotton, abaca, silk, or polyester to create wonderful light, breezy fabrics. Since piña fabric is hand loomed by only a few weavers, it is very precious and scarce, which also makes it expensive.

The piña fiber is used mainly for the Barong Tagalog, also for wedding dresses and other traditional Philippine formal dress. It is also used for table linens, mats, bags and other clothing items. Because it is lightweight but stiff, this sheer fabric can be used in any creative design. Noted couturiers in the local fashion scene are now using the fabric in their creations for haute couture shows worldwide.

Piña’s name comes from the Spanish word “piña” which literally means pineapple. Spanish Red or Native Philippine Red pineapple variety takes about 18 months to reach maturity. They thrive best in open fields with sandy clay soil. The pineapple plant grows spiny leaves up to two meters in length. It is said that the leaves of these varieties yield excellent fibers for handweaving. After about a year from planting, three to five leaves are cut from each plant.

Piña is from a leaf, the leaf has to be cut first from the plant. Then the fiber is pulled or split away from the leaf. Each strand of the piña fiber is hand scraped and is knotted one by one to form a continuous filament to be handwoven and then made into a piña cloth. The green epidermal layer is scraped off the leaf with tools made from coconut shells, coconut husks or pottery shards. Extraction from the long, stiff leaves is time consuming and labor intensive. These fibers are then spun into soft, shimmering fabrics by hand. Because the fiber is fine and breaks easily, working with it is slow and tedious. Workers are constantly knotting broken threads. The result is a lightweight, transparent fabric that is positively beautiful.

The liniwan, is the finest fiber, used for weaving the piña cloth. The second layer, bastos, is a coarse fiber used in making strings or twine. The finer fiber is called pinukpok. All these fibers are combed to clean them further (usually by the river since it is believed that its water makes the strands whiter) and render them easy for hand knotting into continuous strands. Since the individual stripped fiber is no longer than 30 inches, the fibers have to be knotted. This process is known in the dialect as pag-panug-ot, an utterly delicate and laborious task. A piece of bamboo is fashioned into a blade to cut off the end of each knot.

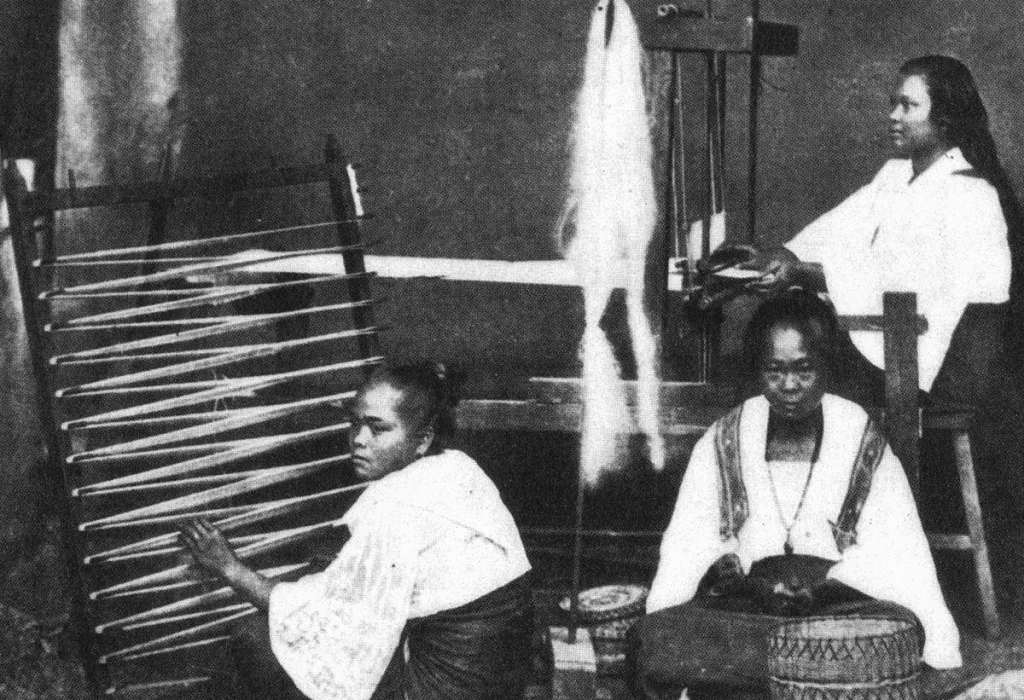

The next step is warping. This is done on pegs struck in a board. Another laborious step, it usually takes 15 to 20 days to warp enough yarns to complete a “sucod” of 18 to 20 “bucos” or 54 to 60 meters of cloth.

Pag-talinyas or spinning is likewise executed with a crude hand-operated bobbin winder which is turned by the right hand while the left hand drills the strand into a tiny mold made of reed or tabun-ak. This process makes the material ready for the loom. The loom has foot-operated treadle with an extended overhead warp beam with two harnesses and two treadles. The warp is wound into the warp beam. Then it is treaded into the boddle (benting) reed or sucod. The benting allows the warp to open when the treadle is stepped on the feet. The sucod is used to press the weft to thicken the cloth.

The thickness and width of the cloth is determined by the sucod. There are the 65, 70 and 80 types of winder. For instance, the 65 sucod produces a cloth of about 24 inches in width; 70 sucod, 29 inches, and the 80 sucod, 31 to 32 inches. Dyeing the fiber to any desired color may be executed at this point. Normally piña is beige or dirty white or ecru but dyed piña produces blue or black piña cloth. These hand woven fabrics are colored with vegetable dyes originating from leaves, and bark of different trees. The result is equally dramatic and charming.

In the olden days, the weavers decided on their own design. The designs usually took the form of flowers, fruits, coconut trees, nipa huts or other designs concocted by the weaver’s imagination. The designs may have been copied from cloths, which have already been designed or inlaid into the fabric with the aid of a graphing paper. In the case of the latter, the design is made on the warp. The traditional decoration for this fabric is a style of hand embroidery called calado. An embroidered piña garment is called piña calado. It takes 8 hours to finish one meter of plain weave cloth, and only one-half to three quarters of a meter may be finished if the cloth has a design. The amount of time spent on the cloth depends on the intricacy of the design. Piña cloth weaving reached its peak of perfection in the late 18th century and in the first half of the 19th century. The decree of the Franciscan chapter of 1580, which urged the teaching of the crafts and trades, has further helped promote piña cloth weaving. The Spanish missionary nuns taught the young girls not only religion, but also other crafts like embroidery that honed the natives’ skills and talents.

The piña fiber and cloth industry is centered in Aklan. Aklan is the main and the oldest manufacturer/weaver of piña cloth in the Philippines. But in recent years, Negros Oriental and Palawan started its own cultivation of pineapple plant of the Red Spanish variety from Aklan aside from conducting skills training program on fiber extraction and weaving. The Aklan piña cloth is woven from the finest mature leaves of native pineapples. Pineapple silk is considered the queen of Philippine fabrics and is considered the fabric of choice of the Philippine elite. Today, piña cloth is being exported to various parts of the world most particularly North America and Europe.